Introduction

In the world manufacturing & AEC (architecture, engineering, and construction) precision is paramount. The advent of cutting-edge technologies has significantly transformed the way professionals approach quality control and reverse engineering processes. Among these game-changing tools, the FARO laser scanner stands out as a beacon of innovation, offering unparalleled accuracy and efficiency. It can capture the shape and dimensions of any object or environment in high resolution and accuracy. In this post, we will delve into the transformative capabilities of the FARO laser scanner and explore its applications in diverse industries.

Unmatched Precision in Manufacturing:

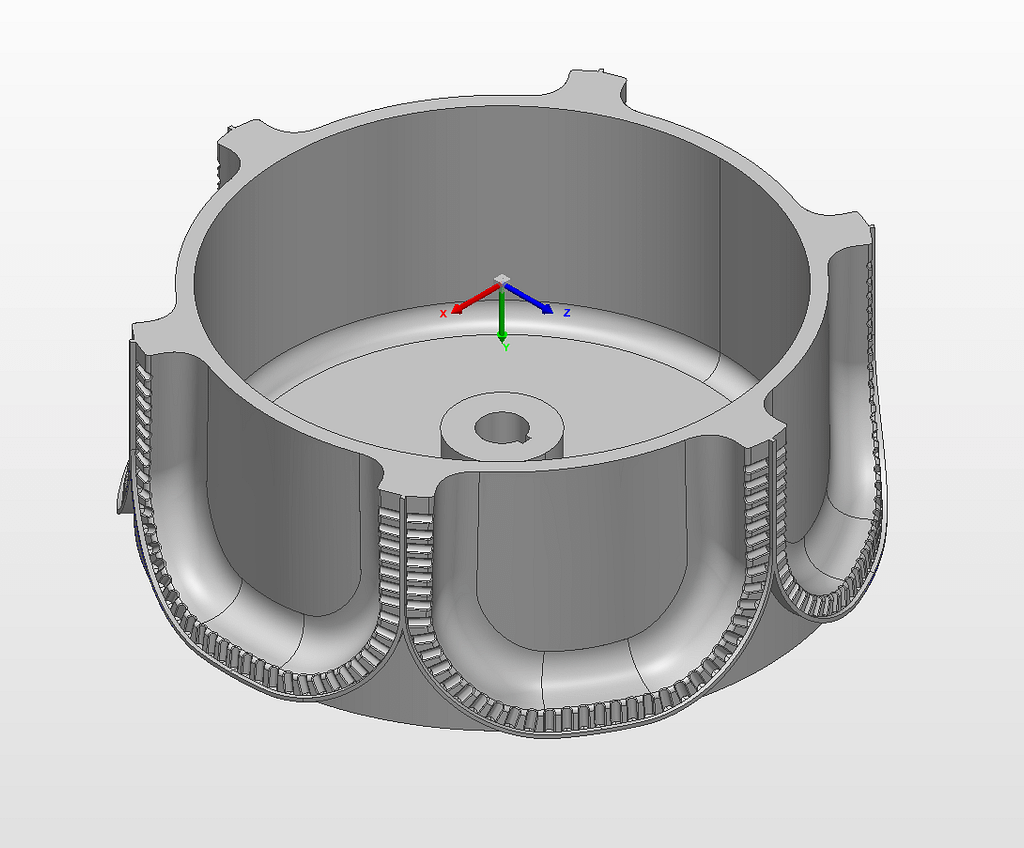

In the realm of manufacturing, precision is the key to producing high-quality products. The FARO laser scanner employs advanced laser technology to capture detailed 3D measurements of objects and environments with an unprecedented level of accuracy. This precision proves invaluable in inspecting manufactured components, identifying deviations from design specifications, and ensuring that each product meets the highest quality standards. Manufacturers can now achieve tighter tolerances and reduce errors, leading to increased efficiency and cost savings.

Architectural Advancements:

Architects and designers rely on precise measurements to bring their visions to life. The FARO laser scanner is a game-changer in the field of architecture, enabling professionals to capture accurate as-built conditions of existing structures. This capability streamlines renovation projects, minimizes design errors, and facilitates a seamless integration of new elements into the existing environment. From heritage conservation to modern architectural marvels, the FARO scanner empowers architects to turn their concepts into reality with unmatched accuracy.

Engineering Excellence:

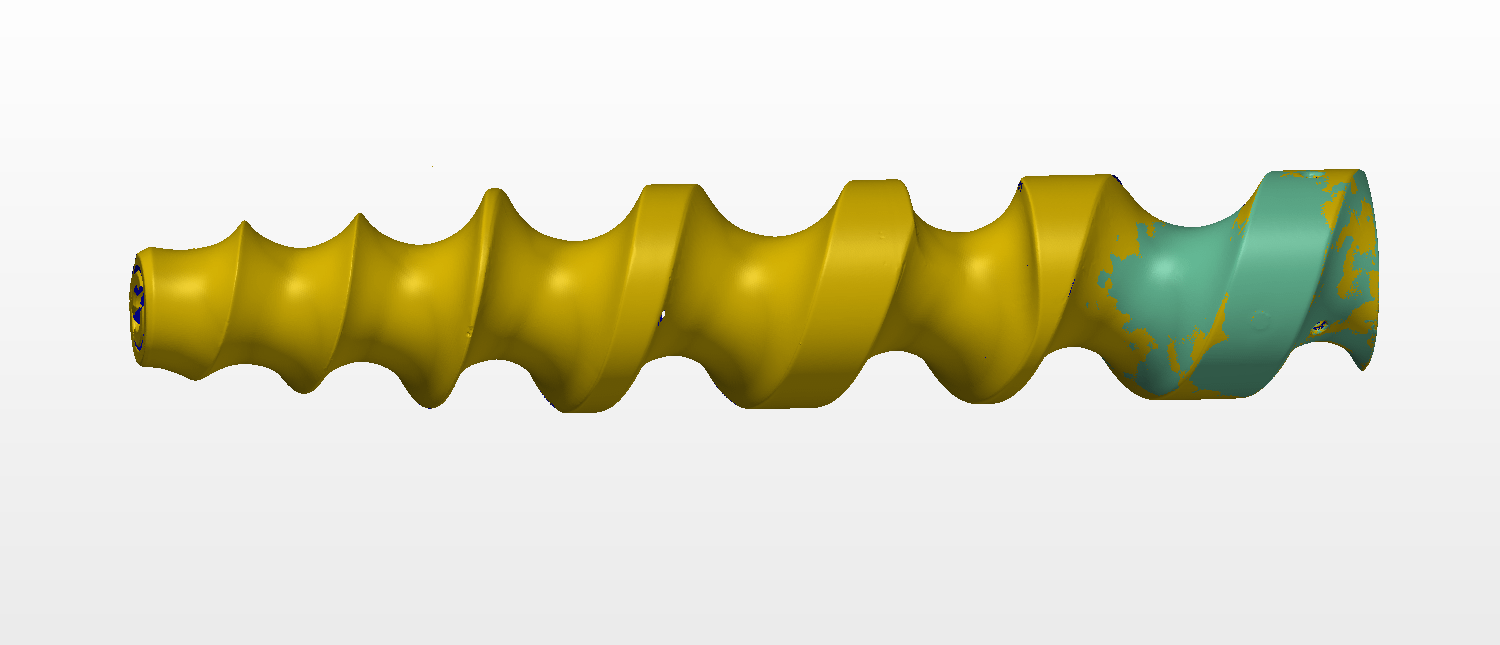

Engineers face the constant challenge of reverse engineering existing components for various reasons, such as product improvement or replacement. The FARO laser scanner simplifies this complex process by swiftly capturing intricate details of physical objects. This non-contact scanning technology eliminates the need for manual measurements, reducing human error and saving valuable time. Engineers can easily create digital models of existing components, enabling efficient redesigns and improvements.

Construction Efficiency:

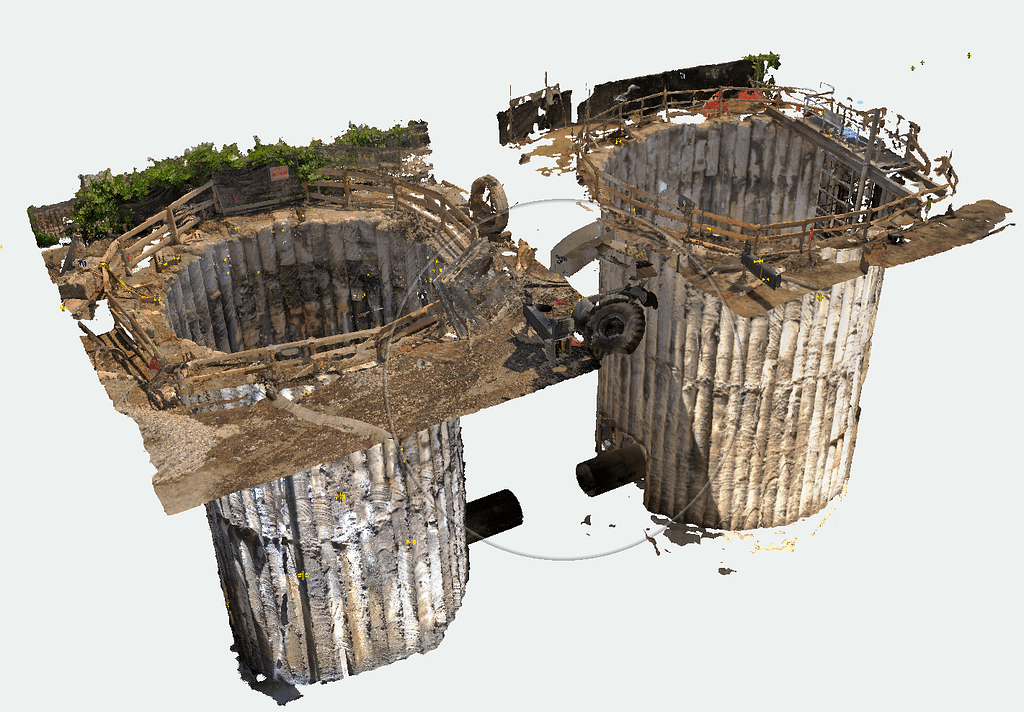

In the construction industry, where precision is crucial for project success, the FARO laser scanner excels in capturing accurate as-built conditions of construction sites. This aids in project planning, clash detection, and ensures that the constructed elements align seamlessly with the original design. The scanner’s ability to rapidly collect comprehensive data also facilitates effective project documentation, enhancing collaboration among construction teams and stakeholders.

Conclusion:

The FARO laser scanner has become an indispensable tool across manufacturing, architecture, engineering, and construction industries, ushering in a new era of precision and efficiency. Its applications in quality control and reverse engineering are reshaping the way professionals approach their work, providing them with the tools to achieve unparalleled accuracy and streamline their processes. As technology continues to advance, the FARO laser scanner stands at the forefront, empowering industries to push the boundaries of what is possible in the pursuit of excellence.

Sales or Service Questions?

We’ve got you covered either way! Please visit our website, email direct or give us a call for all your questions and RFQ’s. We offer quick turn arounds and can scan on site, come see why the team at Frontier Metrology Inc are your trusted 3D scanning and Metrology Experts!

Visit our website: Frontier Metrology Inc

Email us: info@FrontierMetrology.com