3D Scanning

3D Scanning Services

3D Scanning Services, Quality Inspection and Reverse Engineering in Toronto

3D Scanning Technology

Discover the benefits of our 3D scanning services and what we have to offer

Trust our team of 3D scanning and metrology experts to provide fast and accurate 3D Scanning services in 3D scanning, Quality Inspection and Reverse Engineering. With our portable 3D scanning system we will come directly to your location and scan on-site savings time and resources.

Scanning with us

Request an estimate and tell us your requirements

Ship us your parts or we will come directly to you

In-house or On-site scanning

Creation of Meshes, Inspection reports or CAD

Delivery of final deliverable

3D Scanning

Using leading edge 3D scanning equipment and software no job is too big or complex for our team of metrology experts. Whether on-site or in-house we provide quick turn around times. Contact us and learn how we can complement your business or process today!

Our services are currently applied in the following industries:

Automotive

Aerospace & Defence

Tool & Die

Manufacturing

Product Development

Medical

Industrial

Commercial

Deliverables

Polygonal models

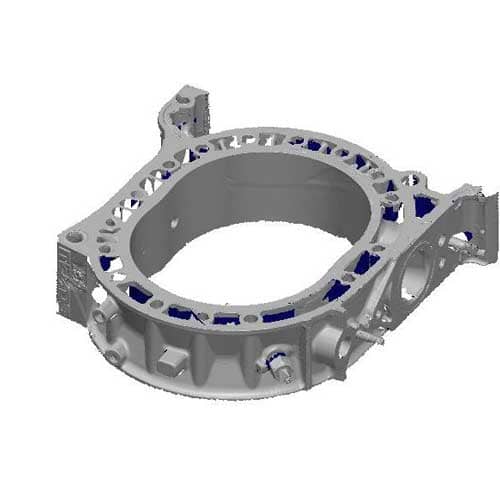

Count on us to accurately digitize your parts, components or full assemblies regardless of material or colour.

Cross-Sections

High detail cross-sections created directly from scan data can be used for inspection, manufacturing or CAD modelling purposes.

3D Print ready models

3D print on virtually any 3D printer using our water-tight polygonal models. We can modify or customize them any way you like.

Let's get started!

Call or email our team for an estimate.

Quality Inspection

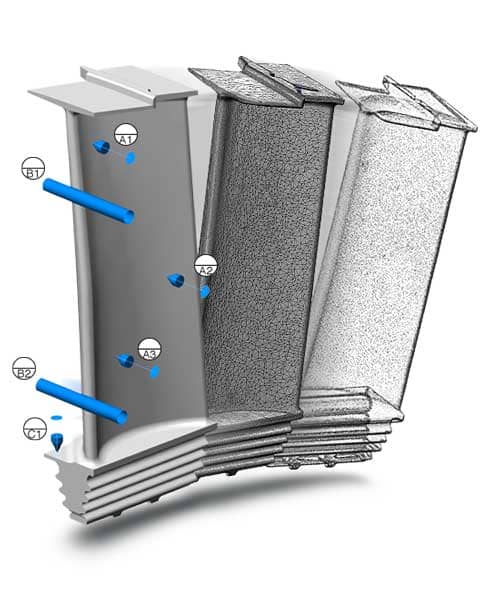

The ability to take scan data and overlay it to existing CAD, check GD&T and probe features exceeds traditional inspection methods. Traditional methods such as check fixtures, gauges and CMM. Even so this can also make a great complement to these methods and be used in conjunction to verify, confirm and troubleshoot as an alternative.

Why inspect?

- Increased quality

- Save on resources

- Reduce scrap and waste

- Real-time results

- Cut down on inspection times

- Rise in production efficiency

- Independent 3rd party inspection

Deliverables

Colour Map Reports

Inspect your parts against nominal CAD using our colour map inspection services. Our colour mapping services inherently use millions of points rather than several compared to traditional methods.

GD&T Inspection

Check your existing GD&T Controls using our GD&T call out inspection. With the ability to pre-program, automate inspection and engineering grade equipment we can provide the accurate data you require.

CMM Style Inspection

Compliment your existing CMM capabilities or verify, confirm and troubleshooting using our CMM style (probing) inspection with increased accuracy and tolerating.

Questions?

We've got answers!

Reverse Engineering

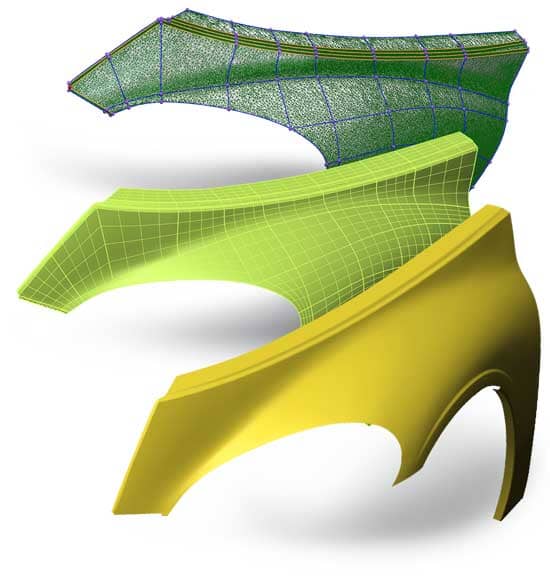

Using high density scan data rebuilding or reverse engineering has never been more reliable and so accurate. Either recreate traditional idealized CAD or use NURBS surfaces to capture unique and free-from surfaces and tooling

Why Reverse Engineer?

- Create your own CAD

- Capture unique and free-from surfaces

- Import directly into CAD/CAM software

- Re-create custom tooling

- Use CAD/NURBS model with existing CAD/CAM software and capabilities

- Modify and update existing CAD

- Catalogue CAD for use at a later date

Deliverables

NURBS Surfacing

Use our generated NURBS surface model to have a true representation of existing parts, tooling or surfaces that are too complex or free-form in nature. Use with your existing CAD/CAM software or CNC machine to replicate custom, broken or unique tooling.

Idealized CAD (Traditional cad)

We can provide you with traditional idealized CAD of your existing parts and equipment for redesigning, engineering, future modification and cataloging. Also compatible with many CAD/CAM software packages and existing CNC equipment.

Reach out today!

We're available 24/7